**Welcome to Durga Packaging Machines - Your Partner for Innovative Packaging Solutions**

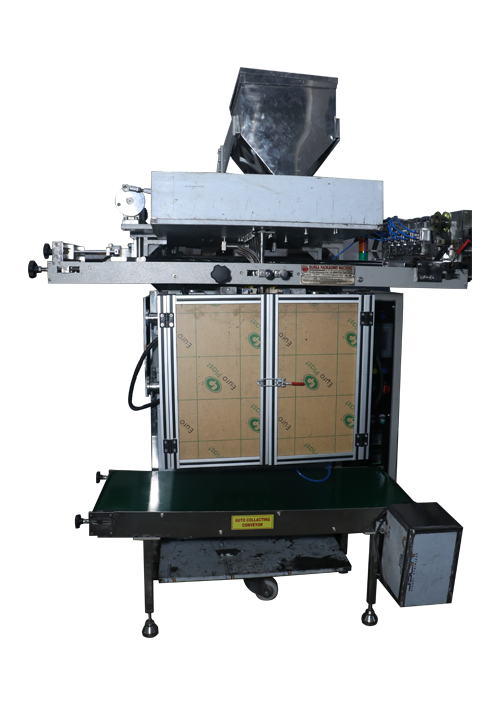

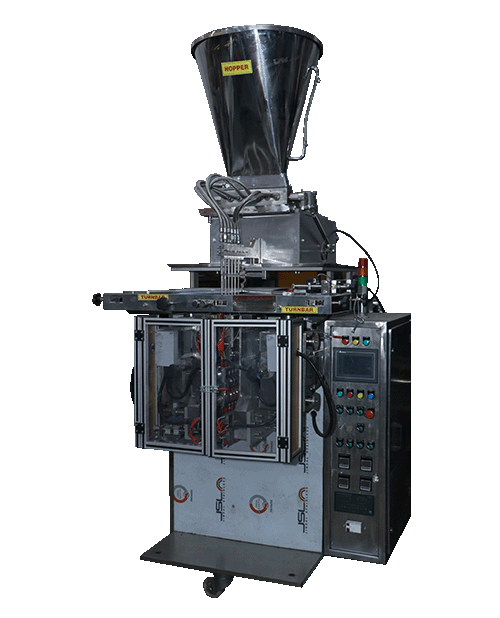

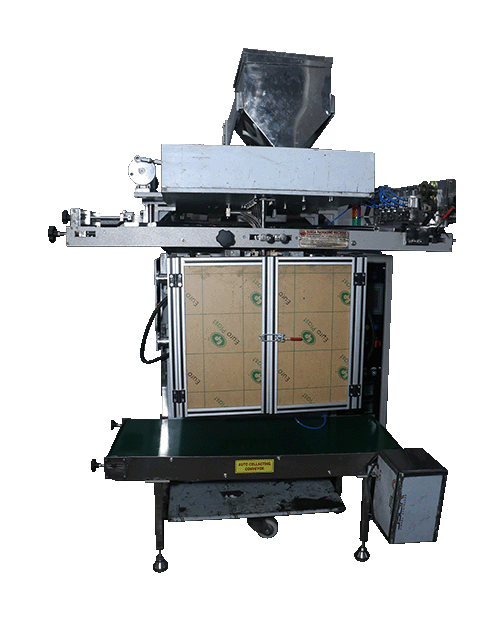

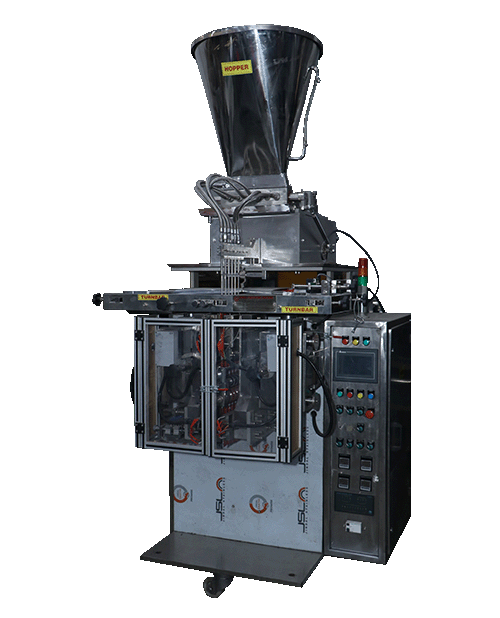

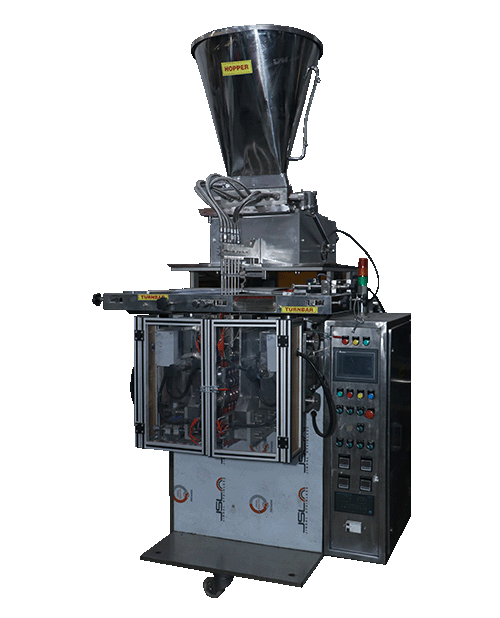

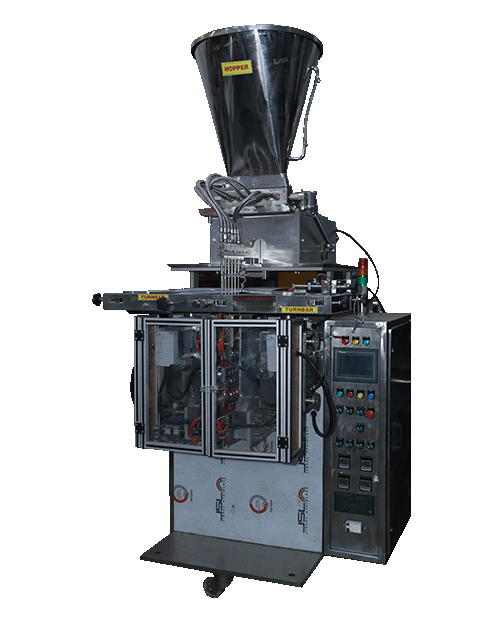

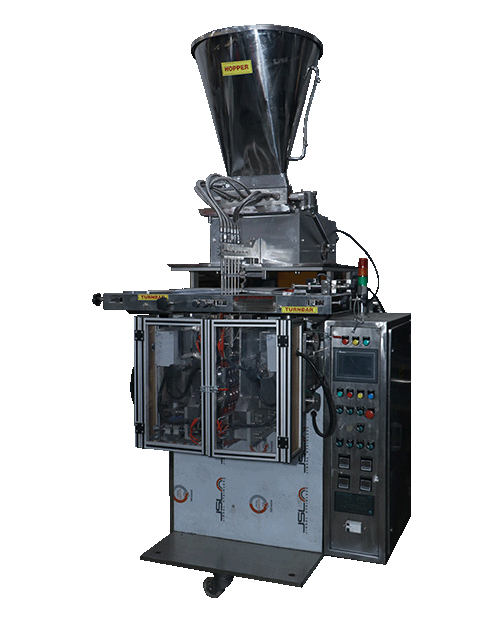

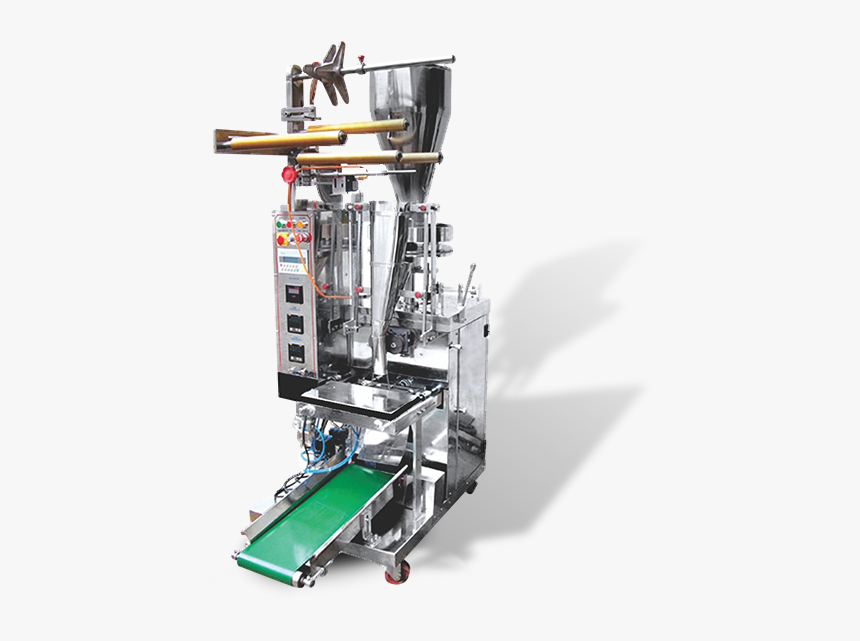

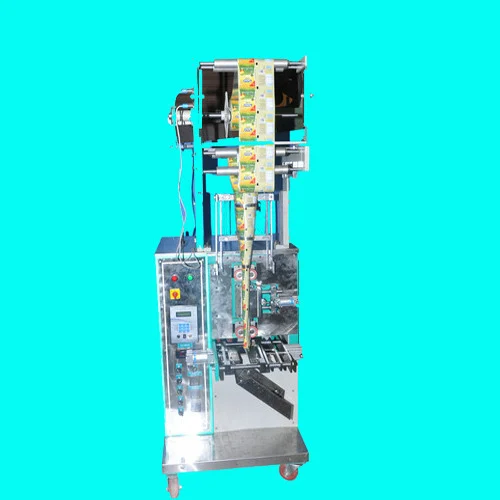

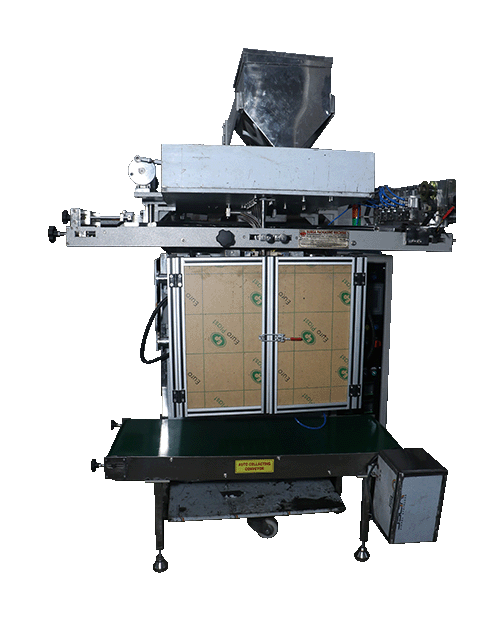

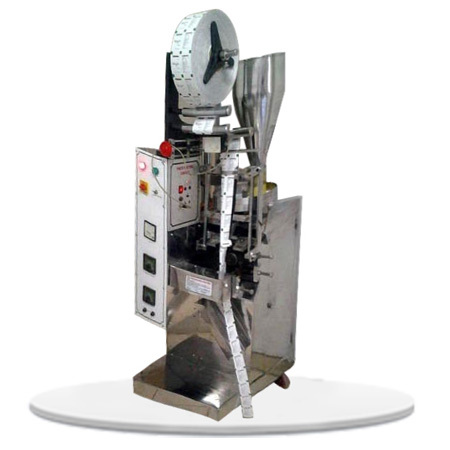

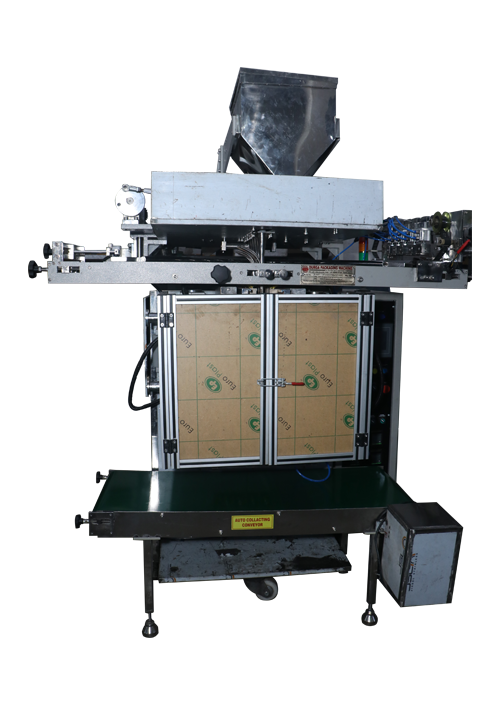

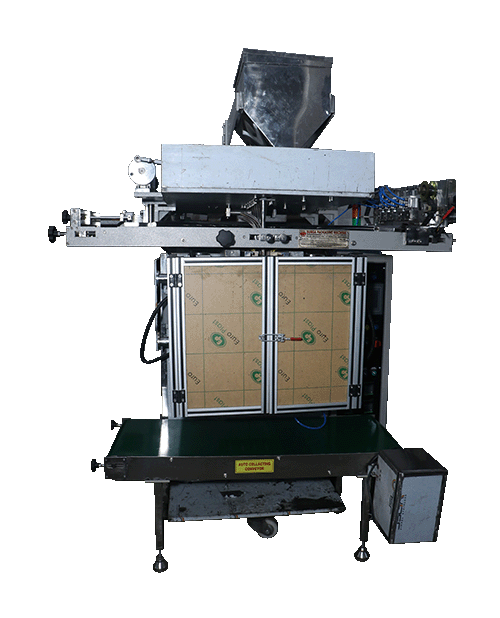

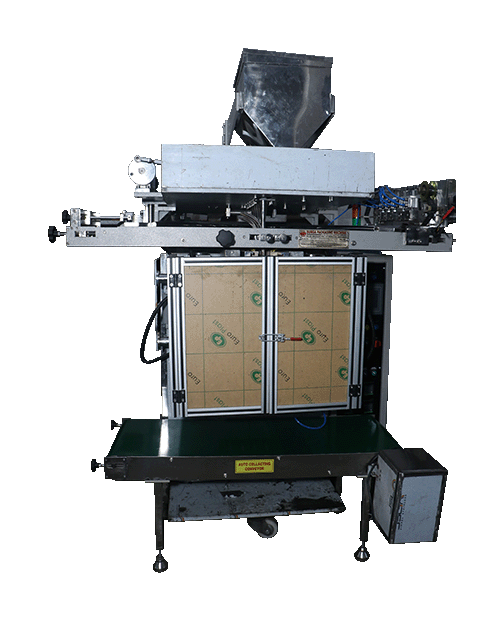

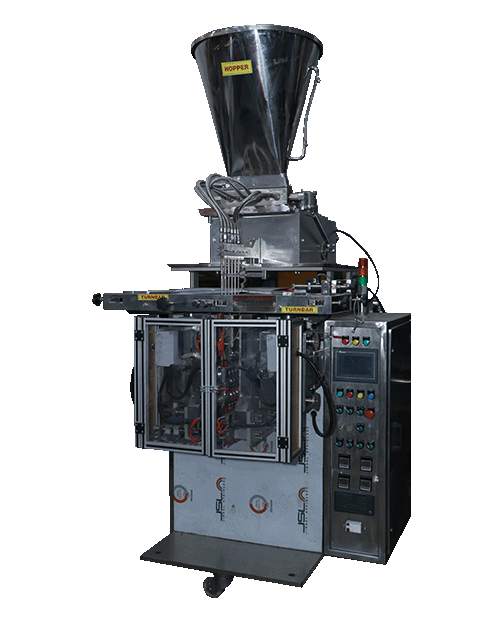

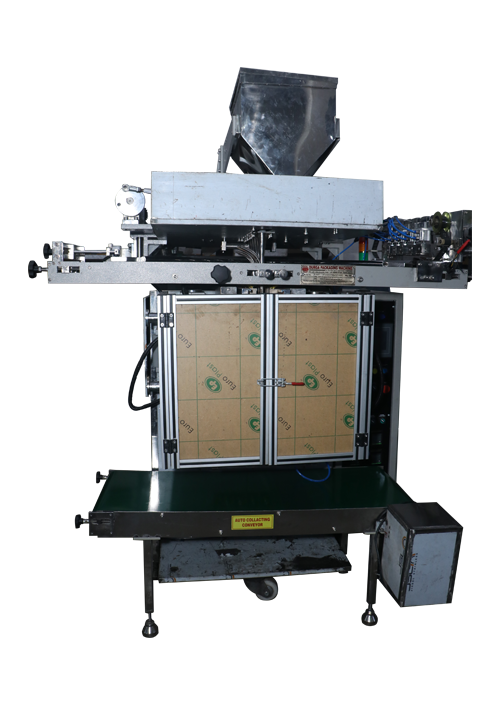

Are you in search of a reliable and efficient solution for packaging Rasna Powder pouches? Look no further than Durga Packaging Machines, a pioneering manufacturer based in mumbai, dedicated to revolutionizing your packaging experience. Introducing our cutting-edge Rasna Powder Pouch Packaging Machine, designed to elevate your packaging process and provide a competitive edge in the market.

At Durga Packaging Machines, we take pride in delivering advanced packaging solutions that stand out from the crowd. Our Rasna Powder Pouch Packaging Machine is no exception. Its USP lies in its ability to seamlessly integrate speed, precision, and versatility, making it a must-have for your packaging needs.

**Key Features:**

1. **Precision Engineering:** Our Rasna Powder Pouch Packaging Machine is crafted with precision engineering, ensuring accurate pouch filling and sealing every time. Say goodbye to wastage and hello to efficiency.

2. **Customizable Packaging:** We understand that every business has unique requirements. Our machine allows for easy customization of pouch sizes, ensuring that your Rasna Powder products are packaged in a way that suits your brand and customer preferences.

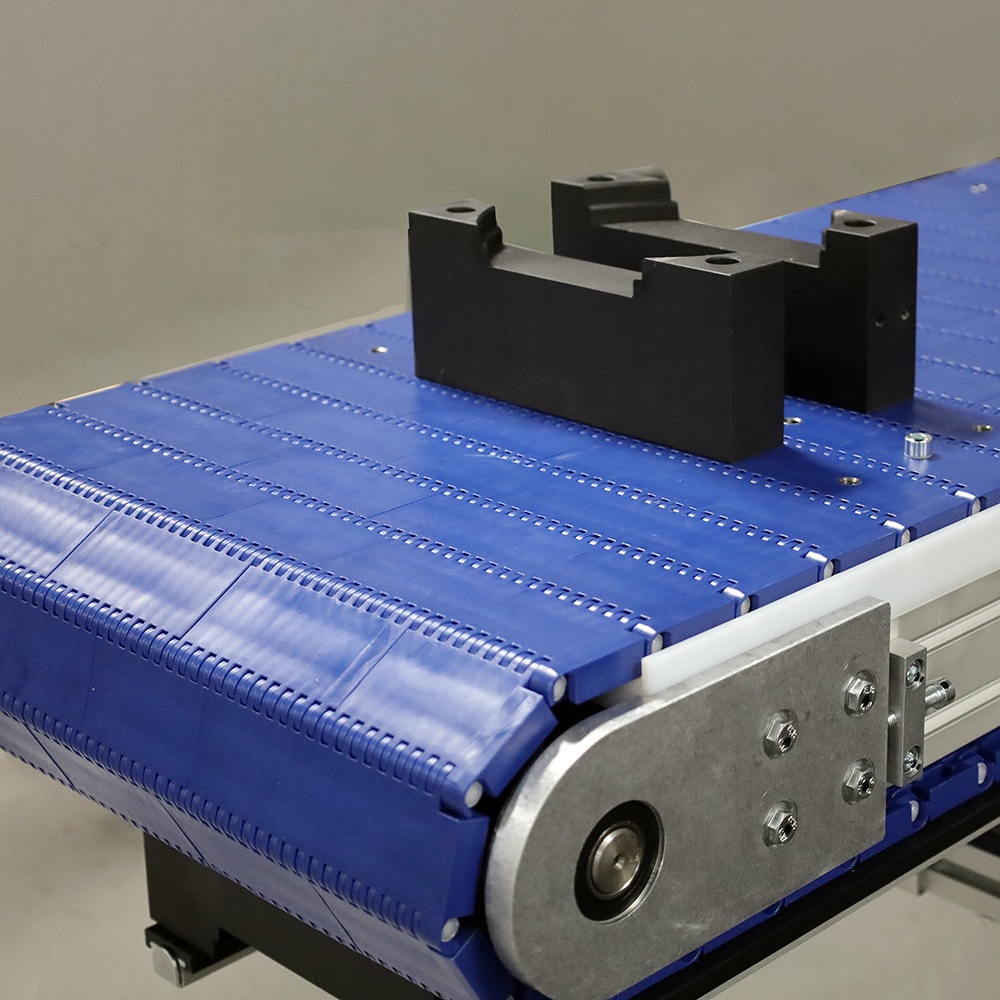

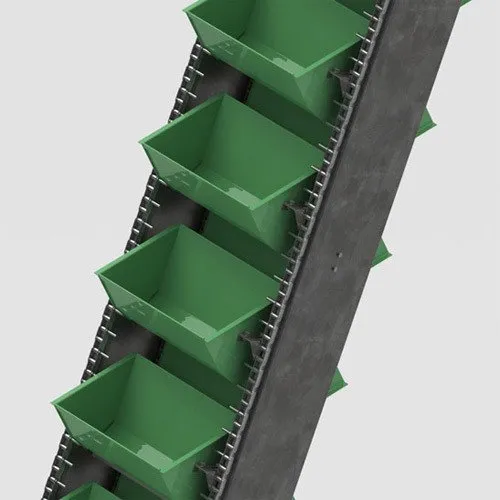

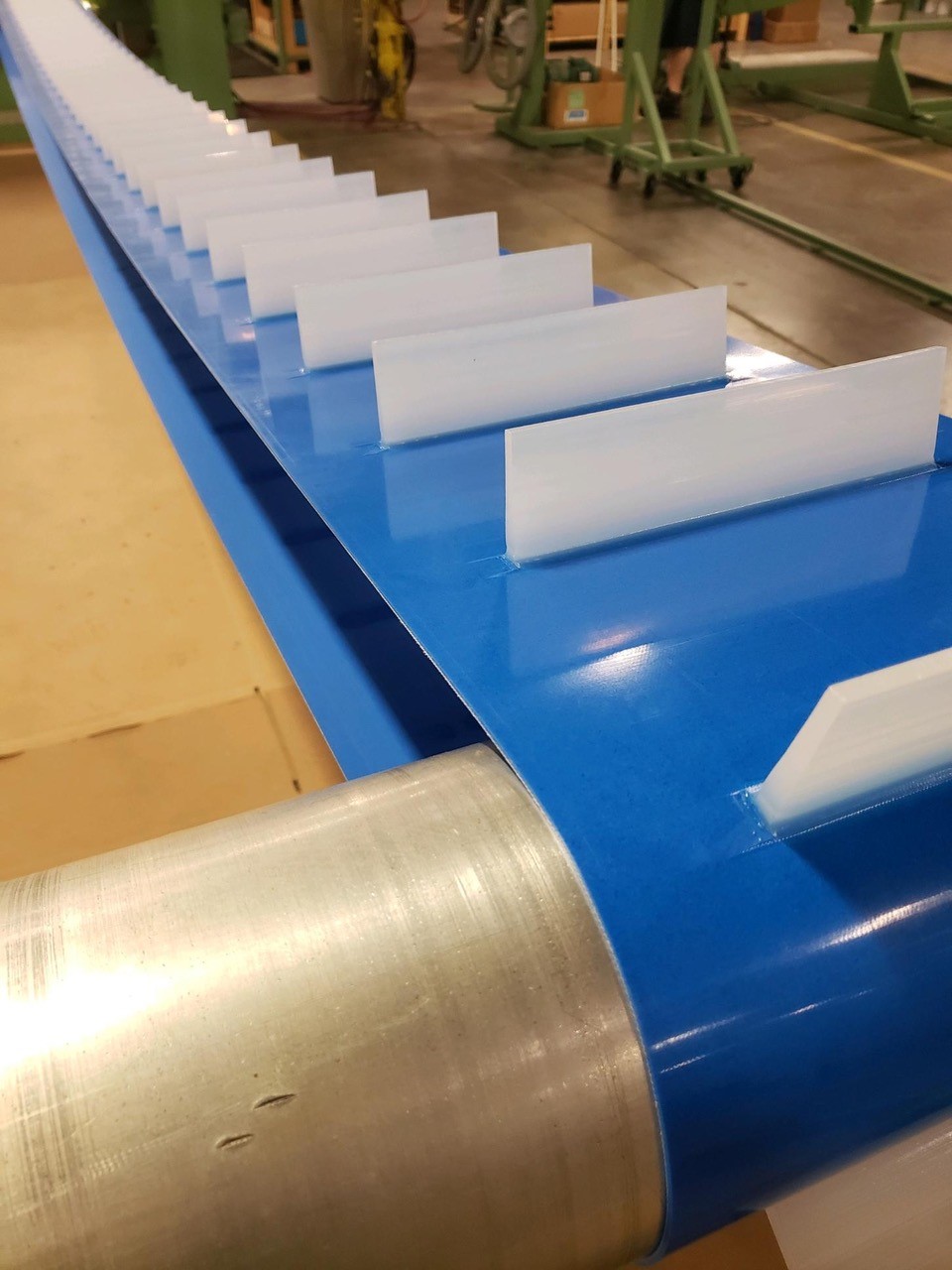

3. **High-Speed Performance:** Time is of the essence in the packaging industry. Our machine boasts high-speed performance, allowing you to meet demanding production targets without compromising on the quality of packaging.

4. **User-Friendly Interface:** You don't need to be a tech expert to operate our machine. With an intuitive user interface, your staff can quickly master the operation, minimizing downtime and maximizing productivity.

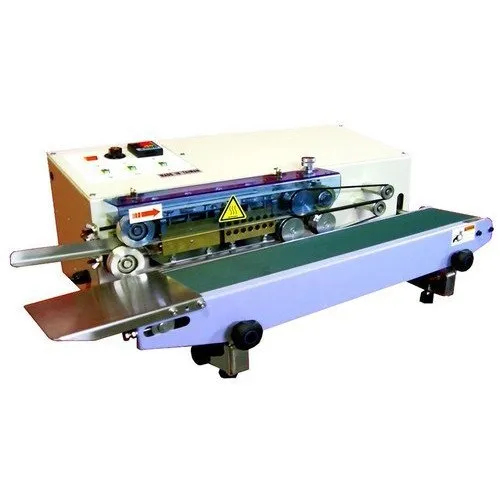

5. **Consistent Sealing:** Maintaining product freshness is vital. Our machine's sealing mechanism guarantees a consistent, airtight seal for your Rasna Powder pouches, extending the shelf life of your products.

6. **Durability:** Built to last, our Rasna Powder Pouch Packaging Machine is constructed using premium materials. It can withstand the rigors of continuous operation, offering you long-term reliability and performance.

7. **Low Maintenance:** We understand the importance of hassle-free maintenance. Our machine's design ensures easy access for cleaning and upkeep, reducing maintenance-related downtime.

**Why Choose Durga Packaging Machines:**

When it comes to packaging solutions, Durga Packaging Machines is a name you can trust. Our commitment to innovation, quality, and customer satisfaction sets us apart. Here's why you should choose us:

- **Experience:** With years of experience in the packaging industry, we understand the evolving needs of businesses. Our Rasna Powder Pouch Packaging Machine reflects our in-depth expertise.

- **Quality Assurance:** We adhere to stringent quality control measures, ensuring that every machine leaving our facility meets the highest standards of performance and durability.

- **Customer-Centric Approach:** Your success is our priority. We work closely with you to understand your requirements and provide tailored solutions that align with your goals.

- **Technical Support:** Our support doesn't end with the purchase. We offer comprehensive technical assistance to ensure smooth installation, training, and ongoing operation of your packaging machine.

Invest in the future of your business with Durga Packaging Machines' Rasna Powder Pouch Packaging Machine. Elevate your packaging process, enhance product appeal, and optimize efficiency – all in one seamless package. Contact us today to learn more about how we can empower your packaging journey in mumbai and beyond.

*Experience Precision Packaging with Durga Packaging Machines - Your Partner for Innovation.*