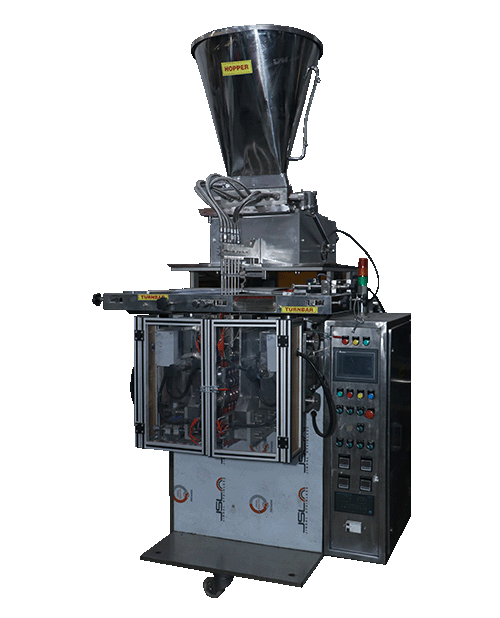

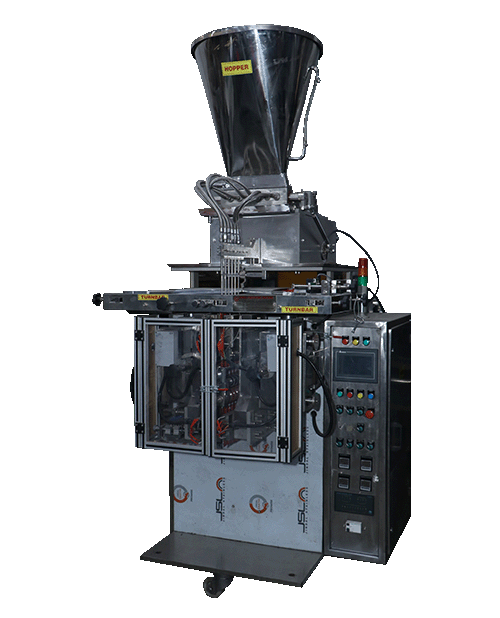

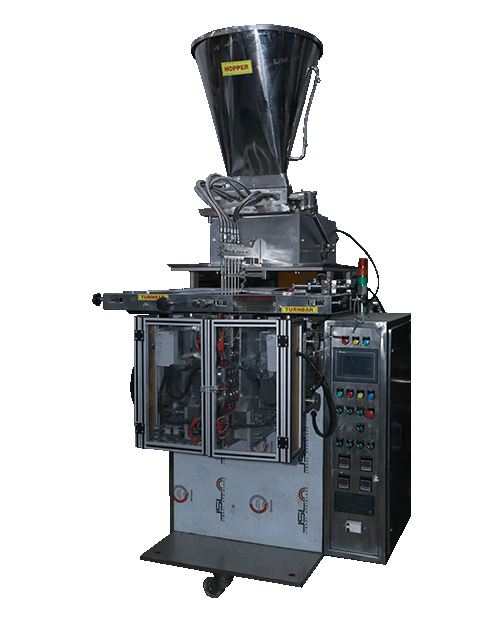

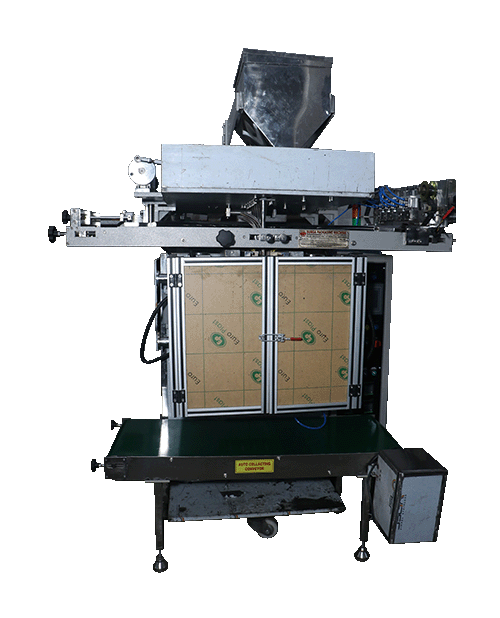

What is a sauce pouch packaging machine?

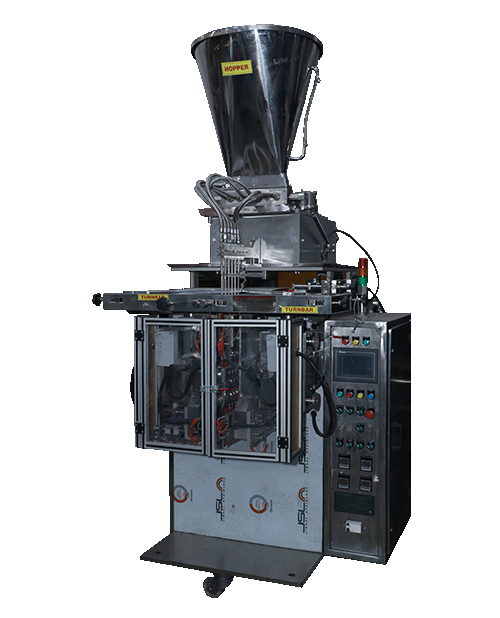

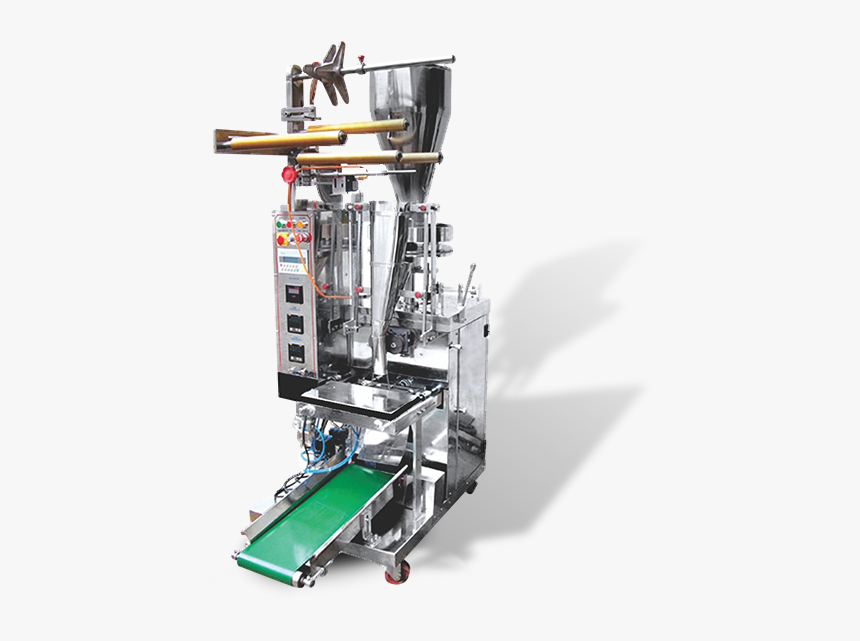

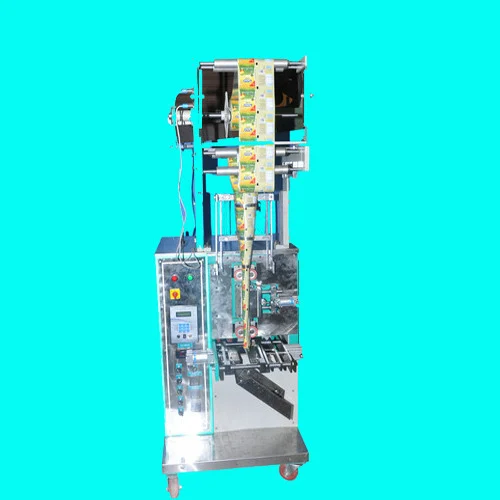

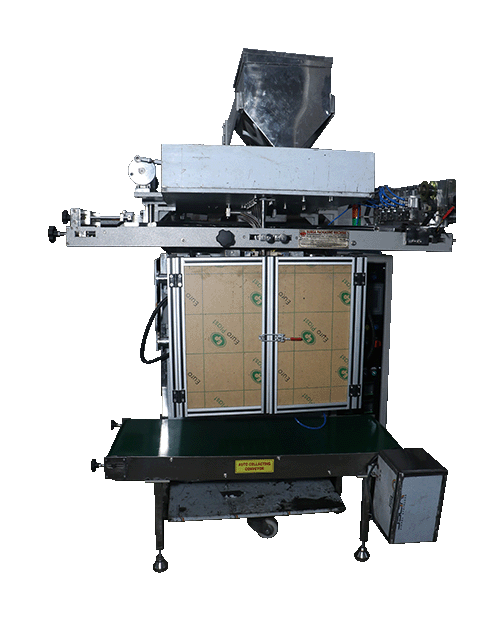

A shampoo pouch packing machine is a specialized piece of equipment used in the packaging industry to automatically fill and seal pouches containing shampoo or other liquid products. It is designed to efficiently package shampoo in various sizes and formats ensuring accuracy and maintaining product integrity.

What are the advantages of using a sauce pouch packaging machine?

A shampoo pouch packing machine works by unwinding a packaging film roll shaping it into a pouch filling the pouch with shampoo using a volumetric or weighing system sealing the pouch cutting it from the film and then discharging the finished pouches for further processing or packaging.

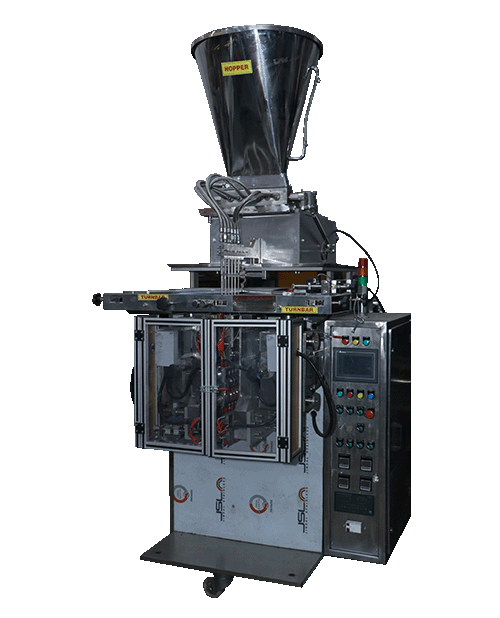

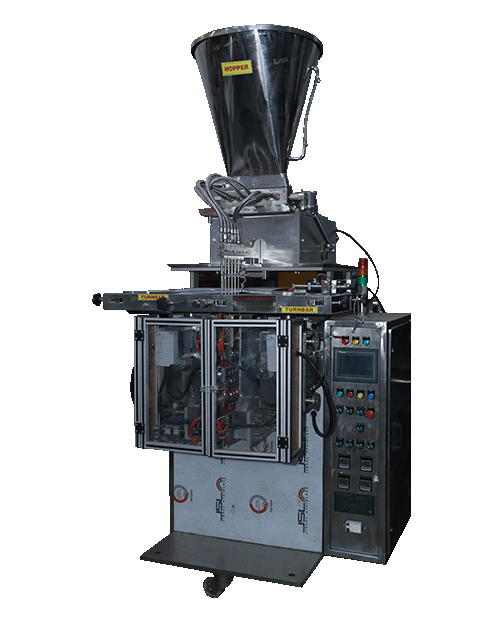

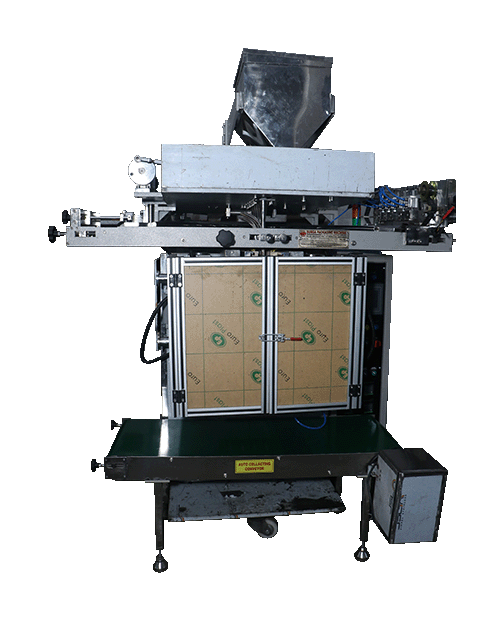

What is a sauce pouch packaging machine?

A shampoo pouch packing machine is a specialized piece of equipment used in the packaging industry to automatically fill and seal pouches containing shampoo or other liquid products. It is designed to efficiently package shampoo in various sizes and formats ensuring accuracy and maintaining product integrity.

What are the advantages of using a sauce pouch packaging machine?

A shampoo pouch packing machine works by unwinding a packaging film roll shaping it into a pouch filling the pouch with shampoo using a volumetric or weighing system sealing the pouch cutting it from the film and then discharging the finished pouches for further processing or packaging.

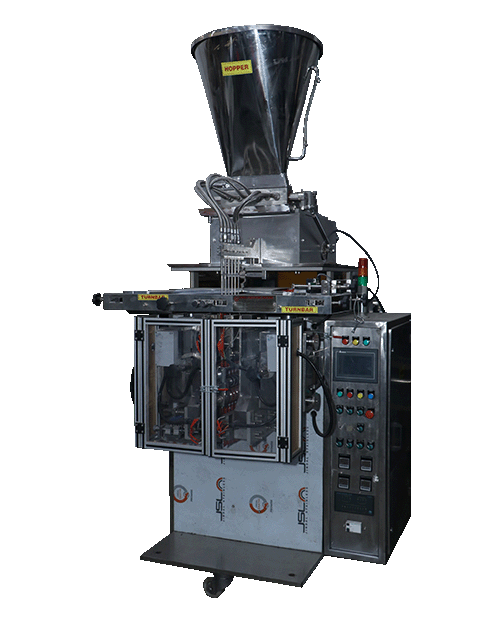

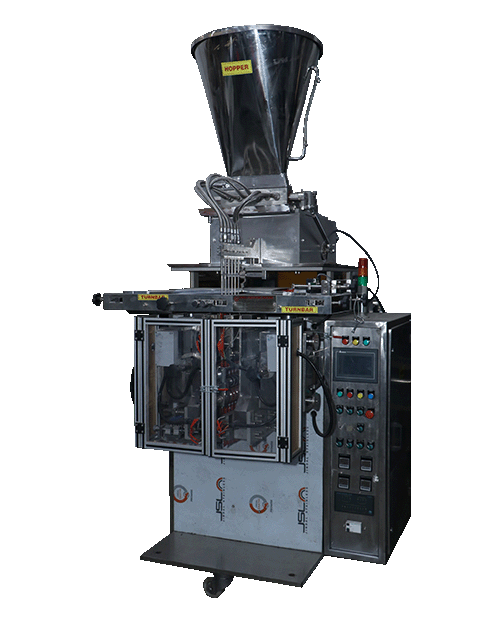

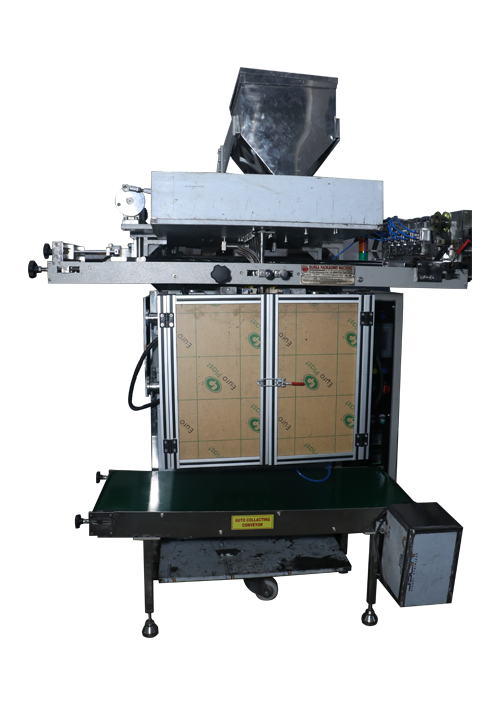

What is a sauce pouch packaging machine?

A shampoo pouch packing machine is a specialized piece of equipment used in the packaging industry to automatically fill and seal pouches containing shampoo or other liquid products. It is designed to efficiently package shampoo in various sizes and formats ensuring accuracy and maintaining product integrity.