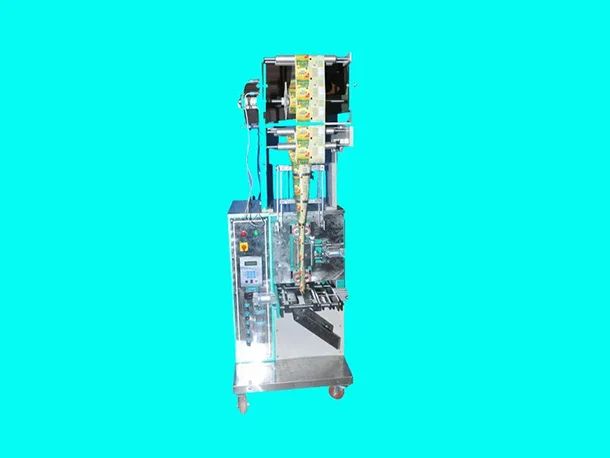

Pouch Packaging Machine

A pouch packaging machine is an automated system that forms, fills, and seals pouches with various products. Think of it as a super-efficient robot designed to create perfect packages every single time. These machines come in all shapes and sizes, catering to different production volumes and product types.

Read More

Multitrack Pouch Packaging Machine

Durga Packaging Machine is one of the best manufacturer and supplier of Multitrack Pouch Packaging Machine in Faridabad.

Read More

Tomato Ketchup Pouch Packaging Machine

Durga Packaging Machine is one of the best manufacturer and supplier of Tomato Ketchup Pouch Packaging Machine in Faridabad. They’ve been in the business for years, providing top-notch packaging solutions to businesses of all sizes.

Read More

Ketchup Multitrack Pouch Packaging Machine

Ketchup Multitrack Pouch Packaging Machine**. Durga Packaging Machine is one of the best manufacturer and supplier of **Ketchup Multitrack Pouch Packaging Machine** in Faridabad. They are known for their high-quality machines, robust construction, and excellent customer service.

Read More

Sauce Pouch Packaging Machine

Durga Packaging Machine offers a range of Sauce Pouch Packaging Machines, catering to various production volumes and pouch specifications. Whether you’re a small-scale sauce producer or a large-scale manufacturer, they have a solution to fit your requirements.

Read More

Pickles Pouch Packaging Machine

Durga Packaging Machine, a prominent manufacturer in India, offers the Pickles Pouch Packaging Machine, a fully automatic solution tailored for the pickle packaging industry. This state-of-the-art machine is designed to pack pickles of various sizes and quantities with precision and speed.

Read More

Shampoo Pouch Packaging Machine

Shampoo Pouch Packaging Machine is a machine designed to automatically fill and seal shampoo (or similar liquid products) into pouches. The “multitrack” part is key – it means the machine can create multiple pouches simultaneously, significantly increasing production speed.

Read More

Hair Oil Pouch Packaging Machine

Lead Storage stands out as a premier Hair Oil Pouch Packaging Machine manufacturer in Delhi, offering superior cable management solutions tailored to meet diverse industrial and commercial needs. Our expertise lies in designing and manufacturing durable, efficient, and cost-effective Hair Oil Pouch Packaging Machines that provide an organized approach to managing electrical and data cables. With years of industry experience, we have built a reputation for excellence, reliability, and innovation in Hair Oil Pouch Packaging Machine manufacturing.

Read More

Mayonnaise Pouch Packaging Machine

A Mayonnaise Pouch Packaging Machine is a specialized form of packaging equipment designed to fill and seal mayonnaise into pouches. These machines play a crucial role in the food processing and packaging industry, ensuring hygiene, efficiency, and consistent quality.

Read More

Ginger/Garlic Paste Pouch Packaging Machine

One of the essential tools used by Durga Packaging Machine is the Ginger Garlic Paste Pouch Packaging Machine. As the name suggests, this machine is designed to automatically fill and seal pouches containing ginger garlic paste – a staple ingredient in Indian and Asian cooking.

Read More

Granules Pouch Packaging Machine

The Granules Pouch Packaging Machine is a specialized packing equipment designed to fill and seal pouches containing granulated products such as pulses, sugar, tea, coffee, spices, detergent powder, seeds, grains, dry fruits, namkeen, and more. These machines are commonly used in food processing, FMCG, pharmaceuticals, and chemical industries for high-speed, hygienic, and precise packaging.

Read More

Gutkha Pouch Packaging Machine

A Gutkha Pouch Packaging Machine is a specialized automated system used for packing gutkha, pan masala, supari (betel nut), and other similar products into small, heat-sealed pouches. These machines are built for high-speed, accurate, and hygienic packaging operations, and are a must-have in the gutkha manufacturing industry where volume and consistency are crucial.

Read More

Liquor Pouch Packaging Machine

A Liquor Pouch Packaging Machine is designed to fill and seal small pouches with measured quantities of liquid liquor, often for country liquor (desi daru), herbal tonics, or similar alcoholic and non-alcoholic beverages. These machines are popular in the alcohol bottling industry, especially for budget packaging where pouches replace glass or PET bottles.

Read More

Mouth Freshener Pouch Packing Machine

A Mouth Freshener Pouch Packing Machine is a specialized packaging system designed to efficiently pack small quantities of mouth fresheners into heat-sealed pouches. These machines are ideal for high-speed, precision-based industries where consistent filling, hygienic packaging, and attractive presentation are key.

Read More

ORS Powder Pouch Packing Machine

Efficient storage is the backbone of every successful warehouse operation. Lead Storage, one of the leading manufacturers of ORS Powder Pouch Packing Machine in Delhi, offers a wide range of innovative and high-quality storage solutions tailored to meet the diverse needs of industries. With a commitment to excellence and customer satisfaction, we provide robust storage systems that enhance productivity, save space, and optimize inventory management.

Read More

Rasna Powder Pouch packaging Machine

The Rasna Powder Pouch Packaging Machine is a high-efficiency, precision packaging machine designed to pack flavored powdered beverages into small, moisture-proof pouches. These machines are widely used in the FMCG and food & beverage industries for retail-ready packaging.

Read More

Servo Auger Powder Filling Machine

A Servo Auger Powder Filling Machine is an advanced packaging system designed to fill free-flowing and non-free-flowing powders with high precision using a servo-driven auger screw. The servo motor ensures consistent and programmable control of the auger’s rotation, allowing for accurate fill weights and minimal wastage.

Read More

Tea Pouch Packaging Machine

A Tea Pouch Packaging Machine is an advanced automated system designed to pack loose or granulated tea into moisture-resistant pouches. These machines are crucial for high-speed, hygienic, and attractive packaging, enhancing product shelf life and branding.

Read More

Tomato Paste Pouch Packaging Machine

The Tomato Paste Pouch Packaging Machine is a fully automatic solution designed for efficient, hygienic, and leak-proof packaging of viscous products like tomato paste, ketchup, sauces, and purees. Using piston or servo fillers, the machine ensures accurate dosing, consistent sealing, and high-speed operation, typically packing 10ml to 1kg pouches at speeds of 20–60 pouches per minute.

Read More

Coffee Pouch Packaging Machine

The Coffee Pouch Packaging Machine is a high-performance, automated system designed for packaging ground coffee, coffee beans, or instant coffee powder into sealed pouches with precision and speed. Ideal for small sachets or large retail packs (typically 10g to 1kg), it uses advanced filling systems like auger fillers for powder or volumetric/weigh fillers for beans. The machine forms pouches from roll film or fills pre-formed pouches, then seals them tightly to preserve aroma and freshness. With stainless steel contact parts, PLC+HMI control, and options like nitrogen flushing, date coding, and zipper sealing, this machine is perfect for maintaining product quality, extending shelf life, and delivering an attractive retail-ready pack.

Read More

Detergent Powder Pouch Packaging Machine

The Detergent Powder Pouch Packaging Machine is a fully automatic packaging solution designed to pack free-flowing powders like detergent efficiently and accurately into sealed pouches. Suitable for a wide range of pouch sizes (from 20g to 5kg), this machine typically uses an auger or cup filler system to ensure precise dosing. It forms pouches from laminated film rolls, fills the detergent powder, and seals them using heat-sealing jaws—ensuring moisture-proof, leak-proof packaging.

Read More

Garam Masala Pouch Packing Machine

The Garam Masala Pouch Packing Machine is a specialized packaging solution designed for efficiently packing fine spice powders like garam masala into airtight, moisture-resistant pouches. Using an advanced auger filler system, the machine ensures precise weight control for pack sizes ranging from 10g to 1kg. It forms pouches from laminated film rolls, fills the garam masala, and seals them securely using heat sealing technology.

Read More

Ghee Pouch Packing Machine

The Ghee Pouch Packing Machine is a fully automatic liquid filling and sealing system designed specifically for packing viscous dairy products like ghee into leak-proof, hygienic pouches. Suitable for packing volumes ranging from 100ml to 1 liter, the machine uses piston or servo pump fillers to ensure accurate and consistent filling. It forms pouches from laminated film rolls, fills the ghee, and seals them using heat-sealing technology to maintain product purity and prevent spillage. Built with stainless steel contact parts and equipped with PLC-based controls, touch screen HMI, and optional features like nitrogen flushing and date coding, this machine is ideal for dairy industries aiming for efficient, safe, and long-lasting packaging of ghee.

Read More

Powder Packaging Machine

The Powder Packaging Machine is a versatile and automated solution designed to efficiently pack a wide range of powdery substances—such as spices, flour, milk powder, coffee, detergent, and pharmaceutical powders—into pouches or containers. Equipped with an auger filler or volumetric cup filler, the machine ensures precise and consistent filling for various pouch sizes, typically ranging from 10g to 5kg. It forms pouches from laminated roll film, fills the powder, and seals them securely using heat sealing technology.

Read More