Ginger/Garlic Paste Pouch Packaging Machine: Everything You Need to Know

Alright, let’s talk about something incredibly useful, especially if you’re in the business of, well, ginger and garlic paste! We’re diving into the world of the Ginger/Garlic Paste Pouch Packaging Machine in Kanpur . You know, those nifty machines that fill and seal those convenient little pouches we often grab from the grocery store?

Imagine manually filling each pouch. Tedious, right? Time-consuming. And inconsistent! A packaging machine solves all those problems. They’re designed for speed, accuracy, and consistent sealing, which translates to more product out the door and happier customers.

Why Use a Pouch Packaging Machine for Ginger and Garlic Paste?

Let’s break down the benefits. It’s not just about automation; it’s about efficiency and quality.

Types of Pouch Packaging Machines

There are several types of pouch packaging machines out there, each suited for different production volumes and pouch styles.

Choosing the Right Machine: Key Considerations

Selecting the perfect Ginger/Garlic Paste Pouch Packaging Machine for your needs requires careful consideration.

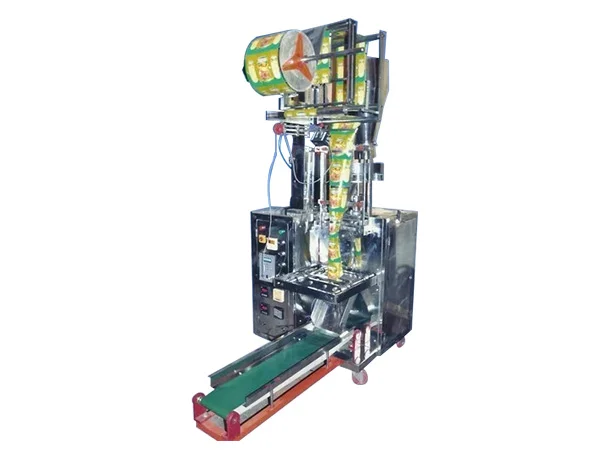

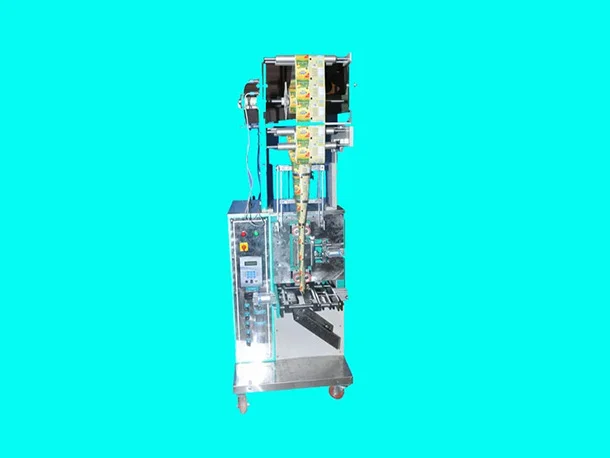

Durga Packaging Machine: Your Trusted Partner

Speaking of reputable manufacturers, let’s talk about Durga Packaging Machine. Durga Packaging Machine is one of the best manufacturers and suppliers of Ginger/Garlic Paste Pouch Packaging Machine.

They offer a wide range of packaging machines designed to meet the diverse needs of the food industry. With a commitment to quality, innovation, and customer satisfaction, Durga Packaging Machine is a trusted partner for businesses looking to automate their packaging processes.

Located in Kanpur, they provide reliable machines and excellent support, helping businesses like yours streamline their operations and improve their bottom line. Their machines are known for their durability, efficiency, and ease of use. Plus, they understand the specific requirements of packaging ginger and garlic paste, ensuring that their machines are perfectly suited for the job.

Specification Table

| Item | Description | Parameters |

|---|---|---|

| 1. | PRODUCT APPLICATION : | TOMATO KETCHUP / SAUCE, GINGER GARLIC PASTE SHEZWAN CHUTNEY / PICKLE PASTE |

| 2. | FILLING RANGE : | 5 TO 100 GM/ML |

| 3. | SEALING TYPE : | 4 SIDE SEAL |

| 4. | PACKING SPEED : | 40 TO 70 STROKES PER TRACK PER MINUTE |

| 5. | FILLING SYSTEM : | VOLUMETRIC |

| 6. | PACKAGING FILM : | HEAT SELABLE LAMINATED FILM IN ROLL FORM |

| 7. | MAXIMUM FILM ROLL WIDTH : | 600 MM/ 800 MM/ 1000 MM |

| 8. | CONVEYOR SYSTEM : | FOR SINGLE CUTTING & MATE SYSTEM |

| 9. | MAXIMUM ROLL DIA : | 400 MM |

| 10. | TEAR : | FROM PERFORATED HORIZONTAL SEAL POINT DEEP V CUT FOR EASY TEAR |

| 11. | MACHINE COVERING : | SS 304 MAKE |

| 12. | PRODUCT CONTACT PARTS : | SS 304 MAKE |

| 13. | AC DRIVE/PLC/MICRO VIEW : | POWER FLEX/SCHNEIDER-TO VARY THE MACHINE SPEED ONLINE |

| 14. | FILLING NOZZELS : | INDIVIDUAL WEIGHT SYSTEM |

| 15. | SEALING : | DOUBLE SEALER SYSTEM (100 % LEAKAGE PROOF) |

| 16. | HEATER : | SAME VERTICAL & HORIZONTAL QUICK SPEED |

| 17. | COMPRESSED AIR REQUIRE : | 2 CFM @6KG/CM SQ. |

| 18. | ELECTRIC POWER : | 7K/W |

| 19. | MACHINE WEIGHT : | APPROX.2050.00KGS |